Attention Nostalgia Super Stock Racers

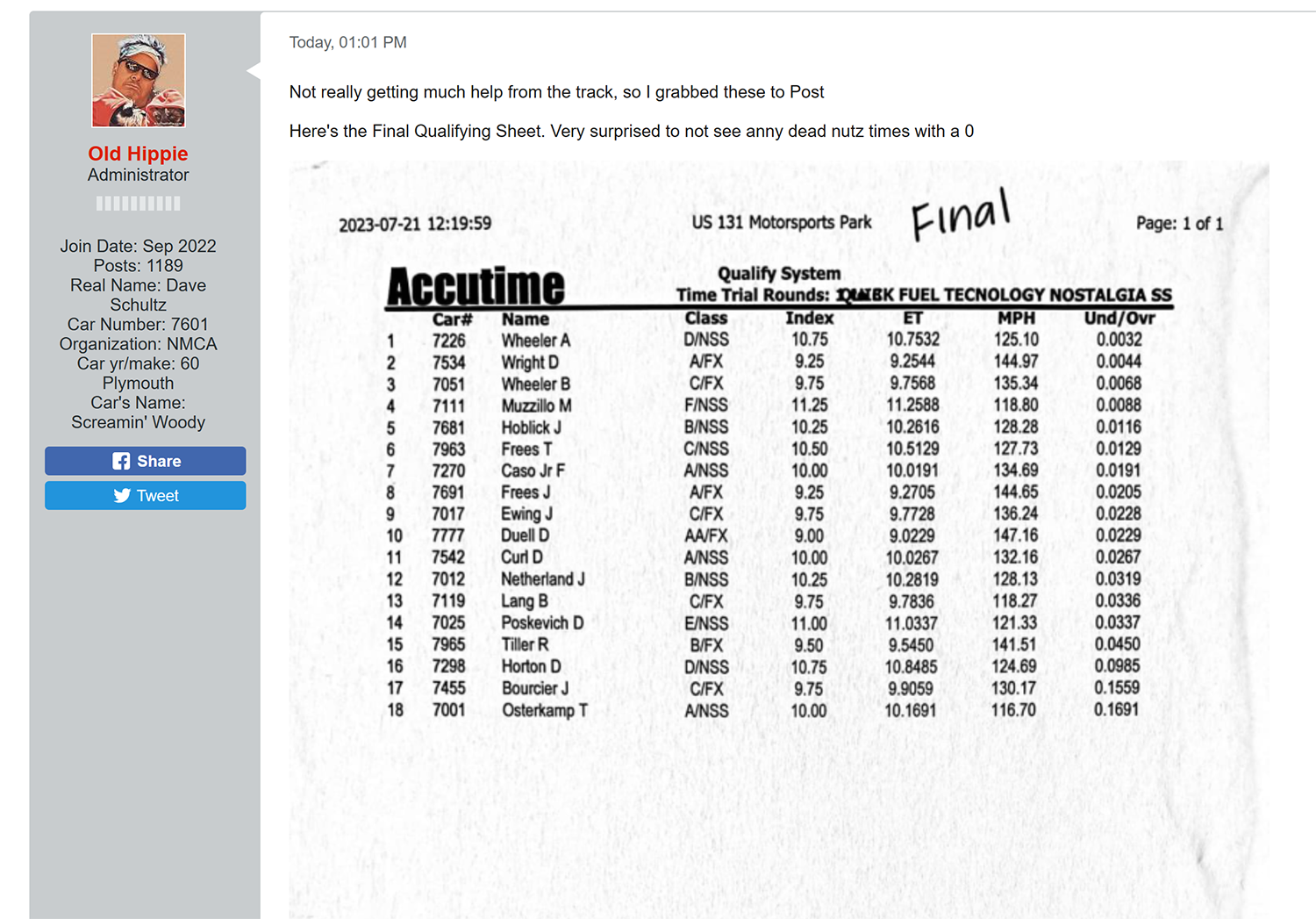

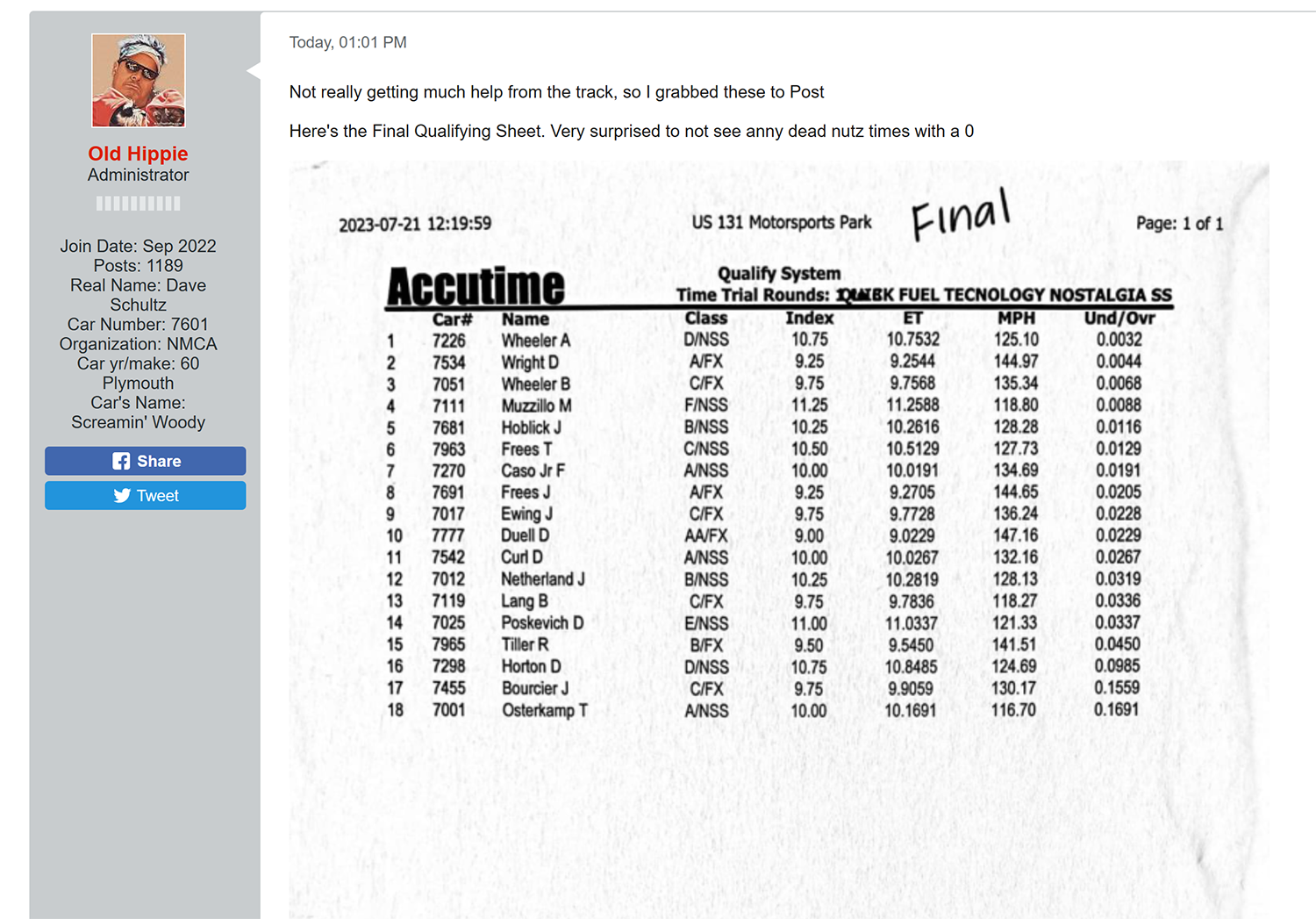

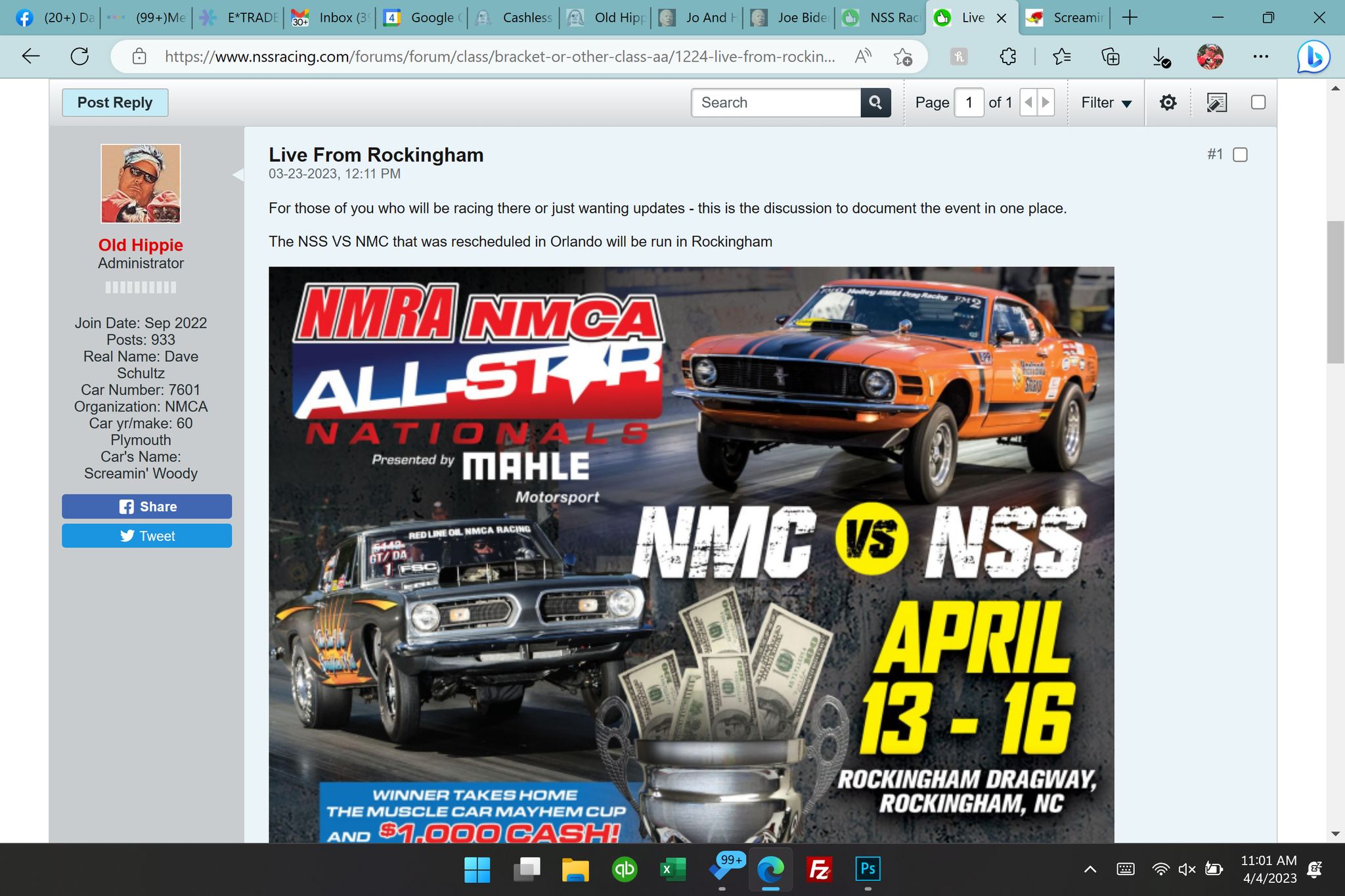

In the NSSRacing forums (https://nssracing.com/forums) there is a discussion with updates on the NMCA race going on in Martin, Michigan. The entire forum is set up to the one best Continue Reading →

In the NSSRacing forums (https://nssracing.com/forums) there is a discussion with updates on the NMCA race going on in Martin, Michigan. The entire forum is set up to the one best Continue Reading →

30% Off Dark T-Shirts – Including Screamin’ Woody Sizes to 5XL at No Extra Charge

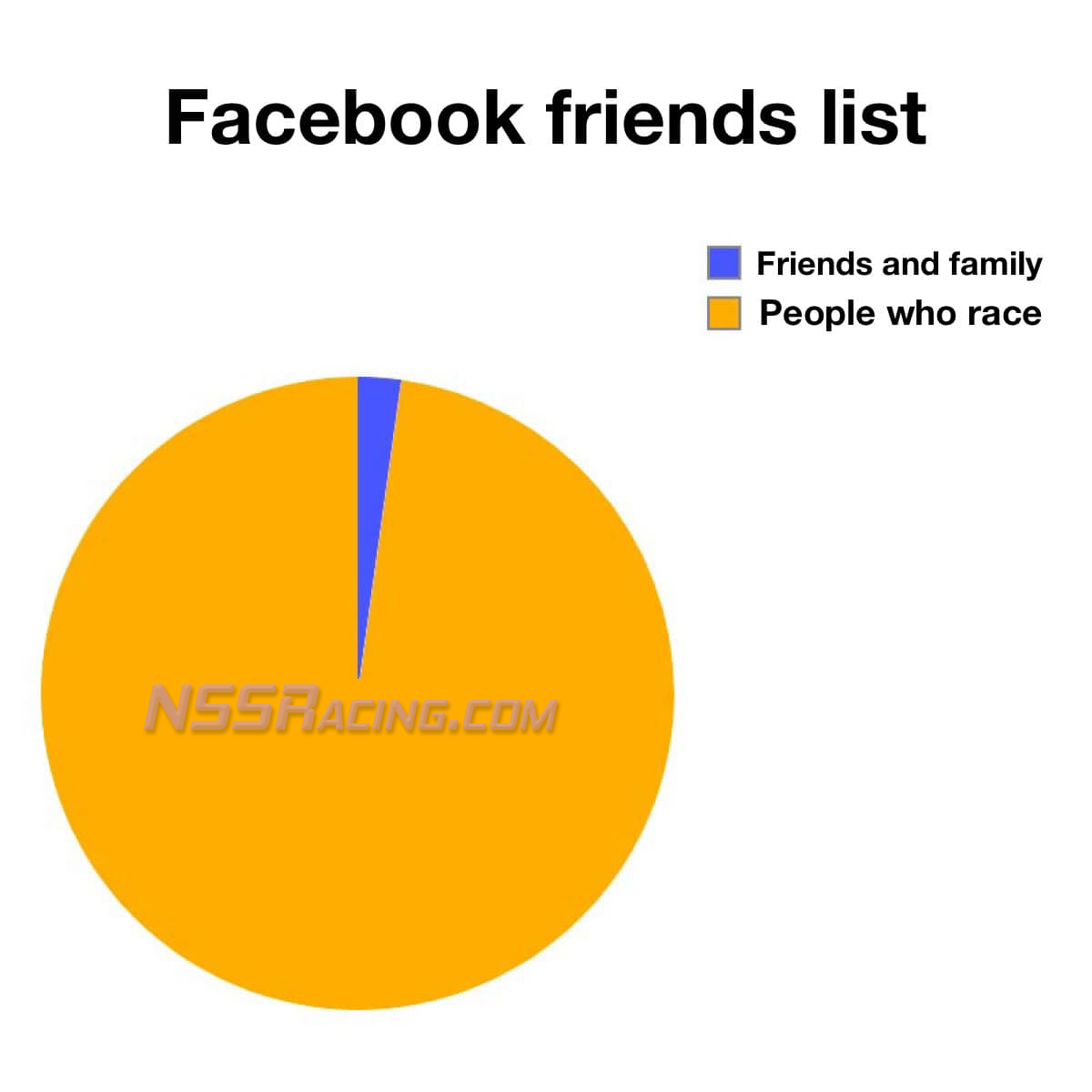

When you post to a group, it is just thrown into a pile of first in and first out of all uncategorized posts. In the case of NSS Racing, a Continue Reading →

https://www.moparstyleracing.com/2023/03/a-little-shop-cleaning-today/ As tomorrow will be thrashing to disassemble the Texas Thug After cleaning off all of the stuff that had been sitting on my transmission table, I washed it, sanded, Continue Reading →

There is a place for those who race in the Index classes. There a place for those running in various organizations for these indexes. There is a place to ask Continue Reading →